Content Background

Urban Agriculture

Urban agriculture, most simply, is the production of crops within city limits. The urban population of the world is estimated to reach 5 billion by 2030 and almost double that by 2050. As humans inhabit and take up more land, the space for agricultural growth becomes limited while the need for food flourishes. Like in a food desert, all populations will demand fresh, healthy foods, making this topic relevant. There are many benefits to urban agriculture, including reducing environmental challenges like climate change, food insecurity, poverty alleviation by providing affordable products and income to growers, and efficient land use.

Urban Farming Technology: Vertical Farming

When most people think of cities, the picture that comes to mind is towering skyscrapers, traffic, and densely populated neighborhoods. This leaves little room to imagine a farm system within the urban landscape; however, vertical farming has solved land scarcity. Vertical farming can range from a small residential scale to a large commercial scale. Plant troughs are arranged in layers within a vertical farming system that can go from several feet to several stories high. The controlled systems can be implemented in abandoned warehouses or buildings, shipping containers, or even homes. The possibility to repurpose unused spaces into vertical farms is only limited by imagination. In addition to solving issues with land scarcity, "Vertical farming can reduce the transportation costs due to its adjacency to the buyer; planned production of herbs and their growing conditions can be enhanced by adjusting the temperature, humidity, and lighting conditions. Indoor farming in a controlled environment needs much less water than outdoor farming because it involves recycling wastewater."7 The opportunity to control a growing environment lends itself to innovation and design. “One commercial forecast suggests that the vertical farming industry will have annual compound growth of 21.3% to reach an estimated value of $9.96 billion by 2025.”8

There are different types of vertical farming methods involving hydroponics. In hydroponic farming systems, plants are grown without soil and are instead planted in a nutrient solution. The hydroponic system is a closed-loop system in which the resources used to grow plants are recycled in the system. The cyclical waste-filtration cycle of these systems allows for organic growth. Aeroponics, which NASA developed, can grow plants using almost no water. Instead, the plants are grown with a nutrient mist rather than an entire solution. This type of vertical farming is still in the development phase. Both will continue to be discussed in further detail throughout this paper.

Figure 1. Lettuce plants are being grown in a vertically-stacked hydroponic system—photograph from the Wikimedia Commons.

The History of Vertical Farming

While the concept of vertical farming might seem relatively new and innovative, the principles of hydroponic gardening date back to ancient times with the Hanging Gardens of Babylon in 600 B.C. and the Aztecs in the 10th and 11th centuries. In the Hanging Gardens of Babylon, it is believed that the gardens were constructed using ziggurat terraces, which allowed for the diversion of freshwater from the nearby Euphrates River to irrigate the gardens.9 In another example, the Aztecs were resourceful when pushed out of their native lands to nearby Lake Tenochtitlan's marshy lands. Because the marshy ground was not arable, the Aztecs developed their hydroponic gardening system in which they created rafts by stringing together reeds. The rafts called "chinampas" were topped with soil dredged up from the bottom of the lake. Vegetables, flowers, and trees grew in the nutrient-dense soil as their roots extended through the raft and into the lake.10

In 1937, Dr. William Frederick Gericke was credited with using the word "hydroponics" to describe his experimentation with growing vegetables without soil. He grew tomato vines more than seven feet long in some of his experiments using only mineral-nutrient solutions. In 1940, he wrote "Complete Guide to Soil-less Gardening '' and is known as the "father of hydroponics".11. After Gericke, an American plant physiologist, Dennis Hoagland, researched the ability of kelp to absorb nutrients from its surrounding environment selectively. This led to developing a nutrient solution, dubbed Hoagland's solution, which is still widely used today.12 In a study conducted as recently as 2014, it was determined that Hoagland's solution produced the most plant growth compared to three other solutions and using an L.E.D. light.13

In 1985, Richard Stoner patented the Genesis Machine's aeroponics system, the first commercially available hydroponics system. In the 1990s, Stoner received funding from NASA to develop a high-performance aeroponics system that could also be used in space. His research was used aboard the M.I.R. space station to grow plants and is still used on the International Space Station. Furthermore, "NASA discovered that the system could reduce water use by 98%, fertilizer use by 60%, and pesticide use by 100%. It also maximizes crop yields by 45% to 75%, and those grown in aeroponic systems had 80% more mass than other methods."14

Vertical Farming Designs

There are six different designs of hydroponic systems. The first type of hydroponic system is the wick system. There is no need for machines or pumps, making it a relatively simple method to set up and maintain. To set up a wick system, you will need a growing pot for the plants and a reservoir for a nutrient solution. Wicks should be inserted through the bottom of the growing pot to hang down into the reservoir. The Science behind the wick system is capillary action. "When [water] gets inside a thin tube or very porous materials, it sticks to the walls. This sticking action creates a curved surface, called a meniscus, at the top edge of the water droplet/molecule. A water drop is held together by the internal bond between its molecules, which creates surface tension. When the adhesive force between the water droplet and the capillary walls is stronger than the surface tension, the water keeps moving upwards. Gravity and the thickness of the tubes/porosity of the material will decide for how long capillary action can continue." The wick system uses capillary actions to draw up nutrients from the reservoir container to the plants.15

Another hydroponics system is the water culture system. In this system, an air pump is required making it an active system. This system is usually designed so that the plant holder floats on the nutrient solution and just one container. An air pump outside the container pumps air through a tube to an air stone at the bottom of the nutrient solution, which bubbles the nutrient solution and provides oxygen to the plants.

Ebb and flow systems, which are popular in more extensive farming operations, have a two-container system is another type of active system. The grow tray, where the seeds and medium are set up, is temporarily flooded with nutrient solution until it drains back into the reservoir. The reservoir is the second container and holds the nutrient solution similar to the wick system setup.

A pump is required to deliver the nutrient solution up into the tray to flood the grow tray. Overflow and gravity are responsible for the draining of the solution back into the reservoir.

Another widely used active hydroponics design is the drip system. Again, at minimum, this is a two-container system with a grow tray and reservoir to hold a nutrient solution. A pump pumps the solution up from the reservoir based on a timer and drips the solution onto the base of the plants through drip lines. Any excess solution not absorbed by the plant escapes via an overflow tube. What happens to this runoff is determined by whether it is a recovery or non-recovery system. In a recovery system, the runoff re-enters the reservoir container from the overflow tube. The nutrient solution is recycled and can be re-pumped through the drip lines again. In this case, the nutrient solution must be monitored and adjusted to maintain optimum nutrient and pH levels. For a non-recovery system, the runoff from plants does not re-enter the reservoir. This allows less maintenance of the nutrient solution.

Nutrient Film Technique (N.F.T.) is one of the most widely known systems of hydroponics. This active system supplies a constant flow of the nutrient solution. The nutrient solution is pumped into the grow tray, where it is set up to flow over the roots of plants and then drained back into the reservoir system. There is no growing medium, and a basket supports the plant with its roots dangling so that the nutrient solution touches them.

The final system design is the aeroponics system. In this system, the roots of the plant are suspended in the air above a nutrient reservoir. A pump located in the reservoir mists the roots of the plants every few minutes based on a timer. Aeroponics is a newer hydroponic technology in the vertical farming industry and will be discussed further in the future innovation section.16

Figure 2. Basic Hydroponics Systems

Photosynthesis

While this unit is focused on vertical farming, photosynthesis is a scientific process that vertical farmers must understand to make the best decisions about their systems. To understand the design of a hydroponics system, we need to consider the minimum requirements that a plant needs to grow. Photosynthesis is an energy-driven process by which plants harvest the energy from light and convert it into chemical energy. It is the underlying process that leads to plant growth. Plants require carbon dioxide (CO2), water (H2O), and light energy to carry out photosynthesis. Plant cells have organelles called chloroplasts, which are the site of photosynthesis. Chloroplasts are made up of two structures: thylakoids and stroma. Pigments called chlorophylls are primarily responsible for absorbing light energy and are located within the thylakoid membranes. Chlorophylls strongly absorb red and blue lights and are responsible for giving plants their green color.17 The absorption of light by these structures can be designated as the first process of photosynthesis occurring during the light-dependent stage.18 When a photon of light hits a reaction center in the thylakoid membrane, an electron is released. The

production of ATP (adenosine triphosphate) and NADPH come from the electron traveling the electron transport chain. Energy from the ATP and NADPH drive the light-independent reactions known as the Calvin cycle. In the cycle, CO2 from the air enters the plant’s stomata and is fixated to form carbohydrates molecules like glucose.19

In addition to understanding plant growth, growers must also understand the environmental factors that affect plant growth and development. Environmental factors that can be modified in a vertical farm system include temperature, light intensity, light quality, humidity, CO2 concentration, air current speed, and nutrient environment. By controlling and modifying these factors, the efficiency of crop production can be altered to produce the desired results for the grower.

Grow Mediums

Any aggregate or material that plants can grow on that lacks plant-nourishing organic compounds can be considered a growth medium. Their purpose is to support the root system of plants and promote a good air and water ratio.20 Almost anything - air included - can be considered a growth medium for hydroponics. There are seven common mediums: Rockwool, oasis cube, expanded clay, coco chips, perlite, vermiculite, and rock. The grower controls the growth medium, who should consider what they are growing and the type of hydroponics system they are using when selecting a medium to work with.21

Nutrient Solutions

Since hydroponics is soil-less, the nutrients found within soil must be accounted for in the nutrient solutions used in a hydroponics system. The three main minerals that plants need the most are nitrogen, phosphorus, and potassium. Nitrogen is essential for plant growth and the formation of leaves and stems. It plays the most active role in the buds and shoots of a young plant. Phosphorus is necessary to ensure the proper growth of flowers and seeds and is used in the energy transport system during photosynthesis. Potassium is responsible for ATP production and opening the stomata of the plant leaves, which allows CO2 entry. When choosing a nutrient solution, you can prepare your own, use a two- or three-part solution, or purchase a pre-made solution. Like the growth medium, the nutrient solution you use depends on the type of plant, growth stage, parts of the plant you want to develop, and external environmental factors like temperature and light intensity.22

Light

Another essential component to understand in a hydroponics system is the light source. Since vertical farms are in indoor environments, the light sources provided to the plants are artificial light powered by electricity. Since plants do not need all types of light for photosynthesis, the types of artificial light used can be selected to maximize plant growth. There are three different types of light to choose from: fluorescent, L.E.D., and H.P.S. grow lights. Fluorescent lights can come in different intensities and last longer than incandescent bulbs.23 High-pressure sodium lights produce a red spectrum light, but they also produce heat and cannot be mounted close to plants.24 Finally, L.E.D. lights are increasing in popularity as the choice for indoor farms. This is because they produce a stable output, have a long life, are compact, lightweight, and control output easily. Also, different from the other light sources, the light emitted from L.E.D.s can be controlled with a source composed of different colored L.E.D.s, the most common combination being red and blue L.E.D.s.25

Vertical Farming Advantages

As you eat a meal from your favorite restaurant, you probably are not thinking about how that food got to your plate. Admittedly, neither do I. In a 2001 study completed at Iowa State University, it was calculated that produce arriving in Chicago traveled approximately 1,500 miles from its source.26 The implications of transportation and fossil fuel use have been linked to perpetuating climate change and greenhouse gas emissions. The U.N. estimates that the world population will grow from 7.7 to 9.7 by 2050, and 70% of that population will live in urban centers.27 By bringing agriculture to the city, we can reduce food miles and increase food accessibility. Vertical farming can provide easier access to areas, like my school's neighborhood, fresh and nutritious produce year-round.

Perhaps the most apparent advantage is year-round crop production. In typical agriculture, crop production corresponds to seasonal patterns, and any unexpected or adverse weather conditions could ruin an entire harvest, affecting agriculture producers and consumers. Because of the controlled environment, extreme weather conditions do not hinder crop production in a vertical farm. This also makes it potentially viable in the most extreme locations like deserts or the Arctic, subsequently addressing accessibility for consumers.

Additionally, vertical farming is a practice that results in zero agricultural runoff. Agricultural runoff is not avoidable in traditional farming practices because crops require more water than they receive from natural rain events. Thus, the accumulation of agrochemicals like fertilizer, pesticides, and herbicides builds up in the groundwater, eventually traveling to local freshwater sources. There is no need to use agrochemicals like pesticides, herbicides, or fertilizers in vertical farming because everything is in a controlled environment.

With a transition to more vertical farming practices, we can also allow current farmland to return to its natural state. If we leave farmland untouched and unaltered, we can assume that the habitat will return to its normal state before farming. Examples of nature being restored to its natural settings when left alone can be seen through examples like the Dust Bowl of the Midwest, Hubbard Brook Ecosystem Study, and the demilitarized zone between North and South Korea.

Agriculture currently accounts for 70% of freshwater usage worldwide for the sake of irrigation.28 As stated previously, crops need more water than what they receive from natural rain events, so irrigation is critical to a crop's harvest. In indoor farming, hydroponics and aeroponics conserve water in their self-contained systems, conserving anywhere from 70-95% less water.

Finally, another advantage to vertical farming is the opportunity to treat wastewater. According to the E.P.A., the United States produces 34 billion gallons of wastewater every day.29 Wastewater is any used water from homes, businesses, and industries and can include human waste, food scraps, oils, soaps, storm runoff, and chemicals.30 If not properly treated and released back into the environment, wastewater can severely affect human and environmental health. Vertical farms can act as a natural wastewater treatment system. In a review from the Oceanographic Research Institute, it was stated that "Due to its high nutrient content, reclaimed water (R.W. or treated wastewater) can be a source of water for hydroponic systems. With special precautions, combining R.W. with hydroponic production makes it possible to obtain safe and viable agricultural produce and provide additional treatment to the R.W. before its discharge to the environment. This is of special importance in arid regions of the world, where freshwater resources are rapidly depleted, and wastewater is discharged into the ocean and other water bodies without any further social or environmental benefit."31

Opportunities for Future Innovation

While there are numerous advantages to vertical farming, there are also disadvantages. However, the disadvantages that will be discussed can be viewed as opportunities for innovation. The first disadvantage to vertical farming is high startup costs to purchase land or buildings within urban districts and the cost of the technology used to control the farm's operations. Of course, initial startup costs mainly depend on location, size, and level of equipment needed. One of the largest vertical farms in New Jersey, AeroFarms, costs $39 million for a 46,000 square foot facility;

whereas an acre of farmland in Iowa is around $8,000 an acre.32 When operating at a larger commercial scale, vertical farming is almost entirely automated by robotics, so even the cost for day-to-day operations can be high, being estimated at $330,000 annually for a facility like AeroFarms.33 To address high startup costs, policymakers can support vertical farming in the future. Policies and initiatives that can support this new industry are including vertical agriculture in city planning, tax incentives, defining the urban market to build a stable source of revenue, and creating opportunities for training and education around this technology.34 Second, the operation is dependent on artificial light to drive photosynthesis, requiring a significant amount of electricity. With ever-improving technologies, the future of vertical farming can be shifted to rely on renewable energies, making electrical systems more sustainable. Third, a new farming industry can threaten the community of conventional farmers. One of the highest costs of conventional farming is labor, and vertical farming seeks to minimize that by relying heavily on artificial intelligence. While some labor-intensive jobs may be lost, the vertical farming industry creates a whole new avenue for agricultural jobs. “Anecdotal evidence demonstrates that so far, the job creations story aligns with this vision. Vertical farming is creating entirely new jobs and drawing from a young, urban, highly-educated population that would be unlikely to pursue traditional farming jobs.”35

The Future of Aeroponics

Between 1975-2010, just 320 patents related to aeroponics had been filed, but there have now been over 1000 filed within the last ten years. "Aeroponics is thought to resolve several plant physiological constraints occurring during hydroponic cultivation. This can include greater oxygen availability within the root bed and enhanced water use efficiency." However, this type of technology requires more sophisticated infrastructure and technology. One study proposes different areas of future research for this type of farming system. A couple of suggested research areas noted from the study: (1) Understand the increased productivity of aeroponic cultivation to inform crop breeding and farm engineering. (2) Investigate the relationship between droplet size, nutrient content, droplet deposition, and plant growth. (3) Understand the relationship between the cycle of environmental factors and aerosol supply and composition.36

Engineering Design Thinking

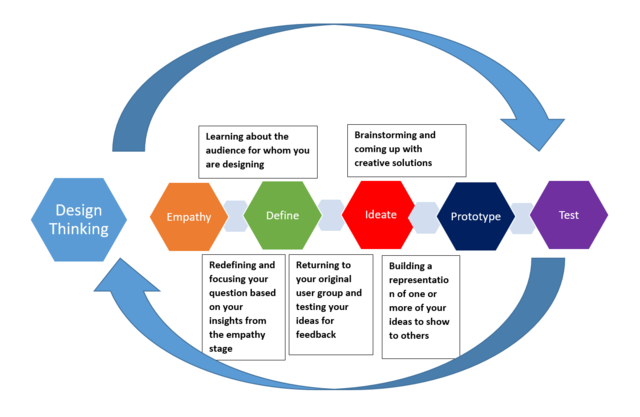

In the development of vertical farms, scientists and engineers engaged in what is known as "design thinking". Design thinking can be broken down into different stages for any development process. The steps are (1) empathize, (2) define, (3) ideate, (4) prototype, and (5) test. In the first stage, empathize, engineers must get an understanding of the problem. They do this by asking questions to those directly and indirectly affected by an issue and may even conduct additional research to understand. Having a clear understanding of the problem leads to the next stage of defining the problem. Defining the problem clearly articulates what a solution must be developed for. Once the problem is defined, an engineer can move on to ideating. Potential solutions are brainstormed during the ideating stage and eventually narrowed down to move to the prototyping stage. Once in the prototyping stage, a prototype is designed to test all or part of a solution. Finally, the prototype moves on to testing. After conducting tests, improvements and modifications to the design can be made in future cycles of the process, and this is repeated repeatedly until a desirable result is achieved.

In this unit, students will have the opportunity to engage in the design thinking process as they are introduced to the concept of food deserts and think about designing solutions for food accessibility in an urban neighborhood.

Figure 3. Design Thinking Process. Photograph from the Wikimedia Commons.

Comments: